Tubing Heads

Tubing head (n.) – Equipment attached to the casing spool used to hang the tubing (smallest casing string) and seal the annulus between the tubing and casing.

Tubing head (n.) – Equipment attached to the casing spool used to hang the tubing (smallest casing string) and seal the annulus between the tubing and casing.

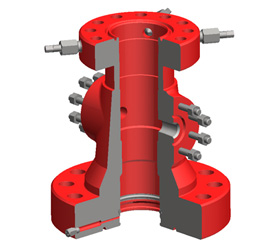

The top spool on a wellhead assembly contains the highest pressure in the wellhead, and contains a load shoulder to hang the tubing hanger and tubing string. When the well is completed, the tree is installed on top of the head with a tubing head adapter. Providing a means to support and test the BOPs while completing the well, the tubing head is a necessary component when drilling and completing a well. The standard tubing head product line combines a straight-bore profile with a varied number of aligning pins, depending on the chosen model. FMC’s tubing heads eliminate the “wedge-locking” of the bowl protector, BOP test plugs, and tubing hangers. As additional advantages, valve removal (VR) threads are standard on all flanged or studded tubing head outlets, and if a 9” or larger top flange is required, the C-29 casing hanger can be used for casing-type completions.

lockdown screw (n.) – A mechanism that actuates the hanger/packoff seals in the event of annulus pressure, preventing casing movement caused by thermal expansion during production

Bottom Connections Bolt-through flange, studded flange and clamp-hub connections are available. The type and pressure rating used must match the top flange of the previous casing spool or crossover flange. Bolt-through flange connections are the most popular and economical type of connection in certain parts of the world. Clamp-hub connections are sometimes specified, because they are much faster to make up and because they reduce the diameter and weight of the assembly when space limitations are present.

Top Connections FMC Surface Wellhead tubing heads have either bolt-through flange or clamp-hub top connections, which are compatible with all FMC tubing head adapters. The producing pressure of the well normally determines the pressure rating of the top connection.

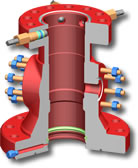

| TC-ET With one aligning pin, the TC-ET accepts all of the standard “TC” tubing hangers, with the exception of a dual-completion hanger. Utilizing elastomer seal technology, the TC-ET can be machined with one or two seals in the bottom prep, depending on your operational requirements.More economical to recondition after well abandonment, the TC-ET is designed with a straight bowl for maximum efficiency. | |

|

|

|

|

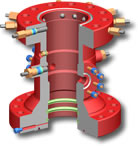

TCM-ET Designed for use with a metal seal, the TCM-ET uses no aligning pins. The option exists, however, to add multiple aligning pins to convert the TCM-ET into the TC-60 or WD-ET for dual completions. |

|

|

|

|

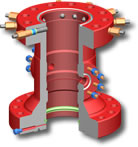

TC-60-ET A model designed for versatility, the TC-60-ET is one of the most widely used tubing heads in the oilfield. Three aligning pins offer compatibility to either single or dual completion, even in tight-delivery situations. No machining modification is required to adapt this tubing head to your well, regardless of the change in circumstances. |

|

|

|

|

TC-WD-ET The “WD” designation in this tubing head indicates a wedge configuration. The wedge is used for alignment on specific types of FMC tubing hangers, with this particular design allowing for the alignment of multiple-string tubing hangers without external manipulation methods. Like all FMC tubing heads, the TC-WD-ET is of a straight-bore design, more economical to recondition after abandonment. |