| FAB STEEL = Housing fabricated from carbon steel pipe and/or weld fittingsDI = A395 Ductile Iron – Economical Class 150 fittings with fixed flanges

CS = A216 Cast Steel – High strength steel fittings with fixed flanges

Flange Material:

DI = ASTM A395 Ductile Iron fixed flanges

FS = Carbon Steel – ASTM A105

CS = ASTM A216 Cast Steel fixed flanges

FV = Full Vacuum FV = Full Vacuum

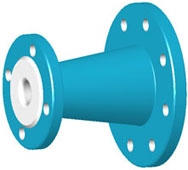

| 150lb PTFE Concentric Reducer |

| Major Size (in) |

Minor Size (in) |

Part Number |

Dimensions |

Housing Material |

Flanges |

Vacuum Rating (in Hg/F) |

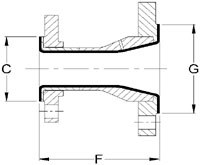

| C |

F |

G |

Material |

R = RotatingF = Fixed |

| 1 |

1/2 |

110705FS |

2 |

4 1/2 |

1 5/16 |

FAB STEEL |

FS |

F |

FV/450 |

| 110705DI |

DI |

DI |

F |

| 1 1/2 |

1 |

115710 |

2 7/8 |

4 1/2 |

2 |

FAB STEEL |

DI |

R |

| 115710FS |

FAB STEEL |

FS |

| 115710DI |

DI |

DI |

F |

| 2 |

1 |

120710 |

3 5/8 |

5 |

2 |

FAB STEEL |

DI |

R |

| 120710FS |

FAB STEEL |

FS |

R |

| 120710DI |

DI |

DI |

F |

| 1 1/2 |

120715 |

FAB STEEL |

DI |

R |

| 120715FS |

FAB STEEL |

FS |

R |

| 120715DI |

DI |

DI |

F |

| 3 |

1 |

530710CS* |

5 |

6 |

2 |

CS |

CS |

F |

| 130710DI** |

DI |

DI |

F |

| 1 1/2 |

130715 |

2 7/8 |

FAB STEEL |

DI |

R |

| 130715FS |

FAB STEEL |

FS |

R |

| 130715DI |

DI |

DI |

F |

| 2 |

130720 |

3 5/8 |

FAB STEEL |

DI |

R |

| 130720FS |

FAB STEEL |

FS |

R |

| 130720DI |

DI |

DI |

F |

| 4 |

1 |

540710CS* |

6 3/16 |

7 |

2 |

CS |

CS |

F |

| 140710DI** |

DI |

DI |

F |

| 1 1/2 |

540715CS* |

2 7/8 |

CS |

CS |

F |

| 140715DI |

DI |

DI |

F |

| 2 |

140720 |

3 5/8 |

FAB STEEL |

DI |

R |

| 140720FS |

FAB STEEL |

FS |

R |

| 140720DI |

DI |

DI |

F |

| 3 |

140730 |

5 |

FAB STEEL |

DI |

R |

| 140730FS |

FAB STEEL |

FS |

R |

| 140730DI |

DI |

DI |

F |

| 6 |

2 |

560720CS* |

8 1/2 |

9 |

3 5/8 |

CS |

CS |

F |

No Vacuum |

| 160720DI |

DI |

DI |

F |

FV/450 |

| 3 |

560730CS* |

5 |

CS |

CS |

F |

No Vacuum |

| 160730DI |

DI |

DI |

F |

FV/450 |

| 4 |

560740CS* |

6 3/16 |

CS |

CS |

F |

No Vacuum |

| 160740DI |

DI |

DI |

F |

FV/450 |

| 8 |

4 |

180740DI |

10 5/8 |

11 |

6 3/16 |

DI |

DI |

F |

FV/450 |

| 180740CS |

CS |

CS |

| 6 |

180760DI |

8 1/2 |

DI |

DI |

F |

| 180760CS |

CS |

CS |

| 10 |

6 |

185760DI |

12 3/4 |

12 |

8 1/2 |

DI |

DI |

F |

FV/240, 18/450 |

| 8 |

185780DI |

10 5/8 |

DI |

DI |

F |

FV/450 |

| 12 |

6 |

190760FS |

15 |

14 |

8 1/2 |

FAB STEEL |

FS |

F |

FV/450 |

| 8 |

190780FS |

10 5/8 |

FAB STEEL |

FS |

F |

| 10 |

190785FS |

12 3/4 |

FAB STEEL |

FS |

F |

* Liner is PFA

** Small side bolt holes are tapped with 1/2-13 UNC 2B threads

| 300lb Flanged – Fabricated Steel Body Only |

|

| Major Size (in) |

Minor Size (in) |

Part Numbers |

Dimensions |

Housing Material |

Flanges |

Vacuum Rating (in Hg/F) |

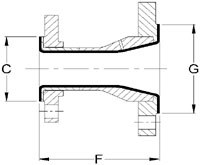

| C |

F |

G |

Material |

F/R = Fixed by Rotating |

| 1 |

1/2 |

110705-3 |

2 |

4 1/2 |

1 5/16 |

FAB STEEL |

FS |

F/R |

FV/450 |

| 1 1/2 |

1 |

110710-3 |

2 7/8 |

4 1/2 |

2 |

| 2 |

1 |

120710-3 |

3 5/8 |

5 |

2 |

| 1 1/2 |

120715-3 |

2 7/8 |

| 3 |

1 |

130710-3 |

5 |

6 |

2 |

| 1 1/2 |

130715-3 |

2 7/8 |

| 2 |

130720-3 |

3 5/8 |

| 4 |

1 |

140710-3 |

6 3/16 |

7 |

2 |

| 1 1/2 |

140715-3 |

2 7/8 |

| 2 |

140720-3 |

3 5/8 |

| 3 |

140730-3 |

5 |

| 6 |

2 |

160720-3 |

8 1/2 |

9 |

3 5/8 |

| 3 |

160730-3 |

5 |

| 4 |

160740-3 |

6 3/16 |

| 8 |

4 |

180740-3 |

10 5/8 |

11 |

6 3/16 |

| 6 |

180760-3 |

8 1/2 |

|

FV = Full Vacuum

FV = Full Vacuum